Intelligent Factory

Exclusive flooring industry

Focus on the flooring industry, to create an exclusive system of the overall scheme

Rapid on-line

It can be launched in 30 days at the fastes

Highest cost performance ratio

Configure on demand, only a tenth of the cost of traditional MES software

The cloud synergy

Seamless integration of data from multiple factories and departments

Professional implementation

Many years of experience in the industry experts field research & implementation

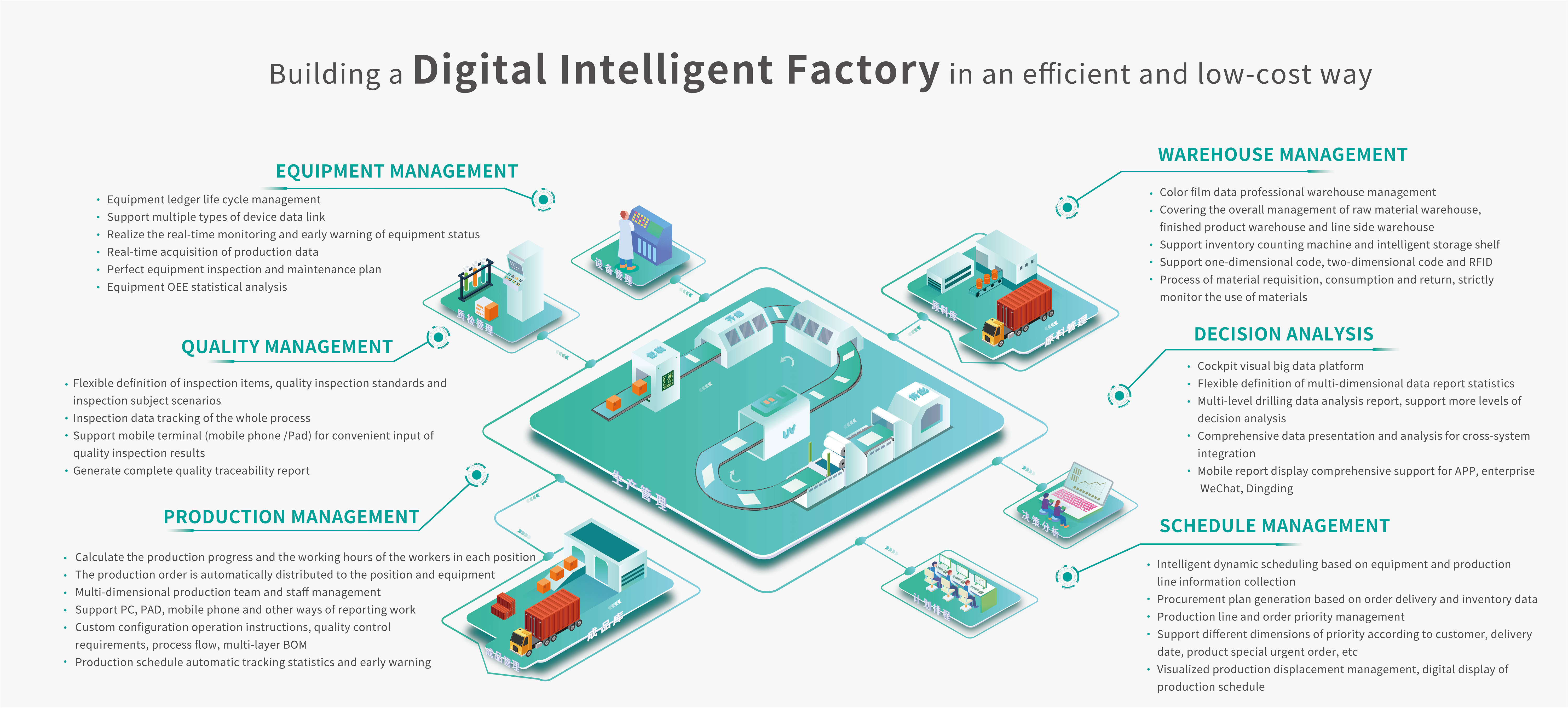

Building a Digital Intelligent Factory in an efficient and low-cost way

Equipment management

Equipment ledger life cycle management

Support multiple types of device data link

Realize the real-time monitoring and early warning of equipment status

Real-time acquisition of production data

Perfect equipment inspection and maintenance plan

Equipment OEE statistical analysis

Quality management

Flexible definition of inspection items, quality inspection standards and inspection subject scenarios

Inspection data tracking of the whole process

Support mobile terminal (mobile phone /Pad) for convenient input of quality inspection results

Generate complete quality traceability report

Production management

Calculate the production progress and the working hours of the workers in each position

The production order is automatically distributed to the position and equipment

Multi-dimensional production team and staff management

Support PC, PAD, mobile phone and other ways of reporting work

Custom configuration operation instructions, quality control requirements, process flow, multi-layer BOM

Production schedule automatic tracking statistics and early warning

Warehouse management

Color film data professional warehouse management

Covering the overall management of raw material warehouse, finished product warehouse and line side warehouse

Support inventory counting machine and intelligent storage shelf

Support one-dimensional code, two-dimensional code and RFID

Process of material requisition, consumption and return, strictly monitor the use of materials

Decision analysis

Cockpit visual big data platform

Flexible definition of multi-dimensional data report statistics

Multi-level drilling data analysis report, support more levels of decision analysis

Comprehensive data presentation and analysis for cross-system integration

Mobile report display comprehensive support for APP, enterprise WeChat, Dingding

Schedule management

Intelligent dynamic scheduling based on equipment and production line information collection

Procurement plan generation based on order delivery and inventory data

Production line and order priority management

Support different dimensions of priority according to customer, delivery date, product special urgent order, etc

Visualized production displacement management, digital display of production schedule

Industry sore point

Delivery time can not be estimated scheduling efficiency is low

Traditional arrangement mainly by manual experience, which is difficult to adapt to complex scenes

Missing orders are common

Production data statistics are paper-based, which cannot be effectively linked, leading to the common occurrence of missing orders

Color film utilization rate is low

Color film quantity mainly rely on the traditional paper management, statistical management is difficult, low utilization rate

Difficult to calculate the wages of staff

Production staff working hour statistics and supervision rely on paper, not timely and accurate

The order cost statistics are inaccurate

The calculation of order cost is with countless data, which cause the inaccurate calculation of order cost

High shutdown rate and damage rate of equipment

Equipment failure without warning, equipment maintenance is not timely, high shutdown rate, high maintenance management cost